What is vacuum double glazing or vacuum insulated glazing?

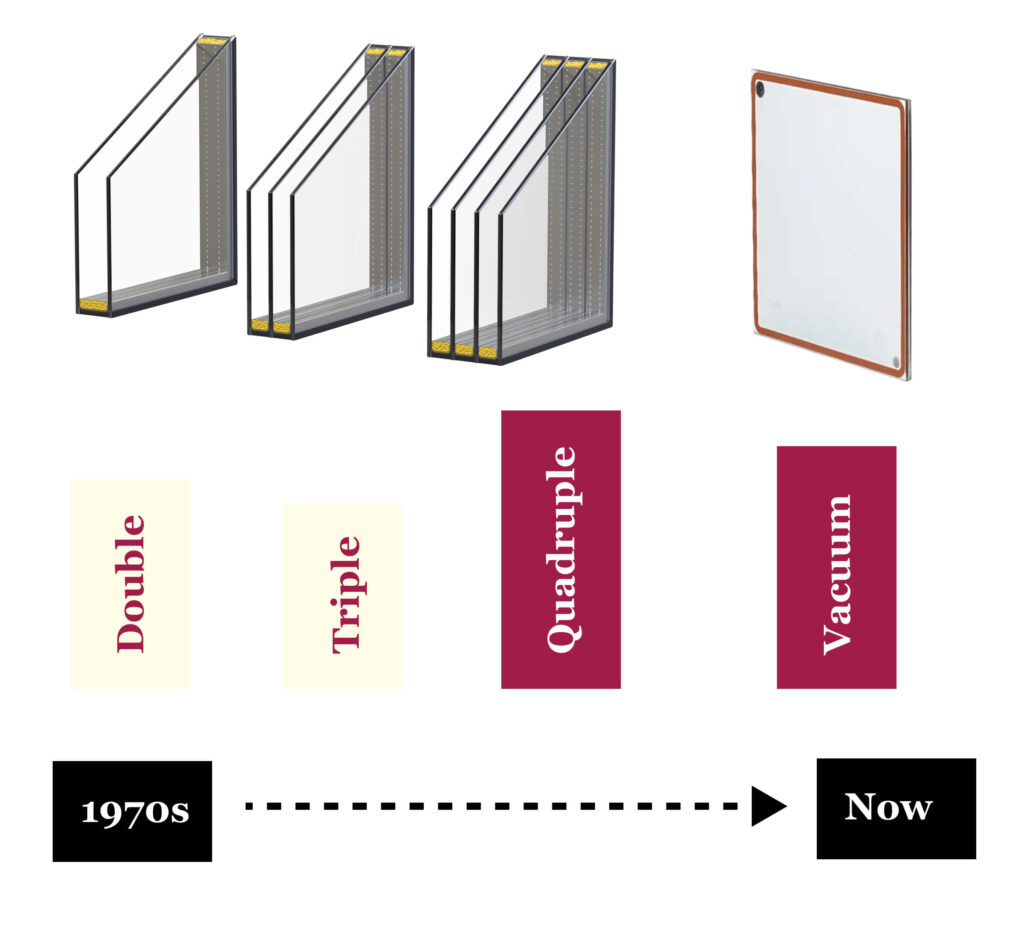

Vacuum insulated glazing (VIG) is the most resent innovation in insulated glassing consists of two glass panes with a 0.1-0.3 mm vacuum gap between them, which virtually eliminates the heat transfer, making it highly energy-efficient.

Vacuum double glazing is particularly suitable for period properties with wooden windows, where maintaining the aesthetic appeal of heritage windows is important while upgrading their performance.

How vacuum double glazing works

The core principle of VIG lies in the vacuum gap between two panes of glass.

This vacuum cavity works as an insulator and prevents heat loss between the interior and exterior of a window.

Traditional double glazing relies on gas-filled cavities (usually argon), but VIG eliminates the gas in favour of a vacuum, which is even more effective at reducing heat transfer.

Tiny, almost invisible pillars hold the glass panes apart, ensuring structural integrity without affecting the clarity of the view.

Unique design features of vacuum double glazing

Vacuum double glazing stands out due to its innovative design elements, which work together to provide superior thermal insulation and long-lasting durability.

Pillars or Spacers

Microscopic spacers (or pillars) are used between the two glass panes to keep them apart, ensuring structural integrity under atmospheric pressure. These spacers are typically made from materials like ceramic or metal and are often 0.2mm to 0.5mm in diameter.

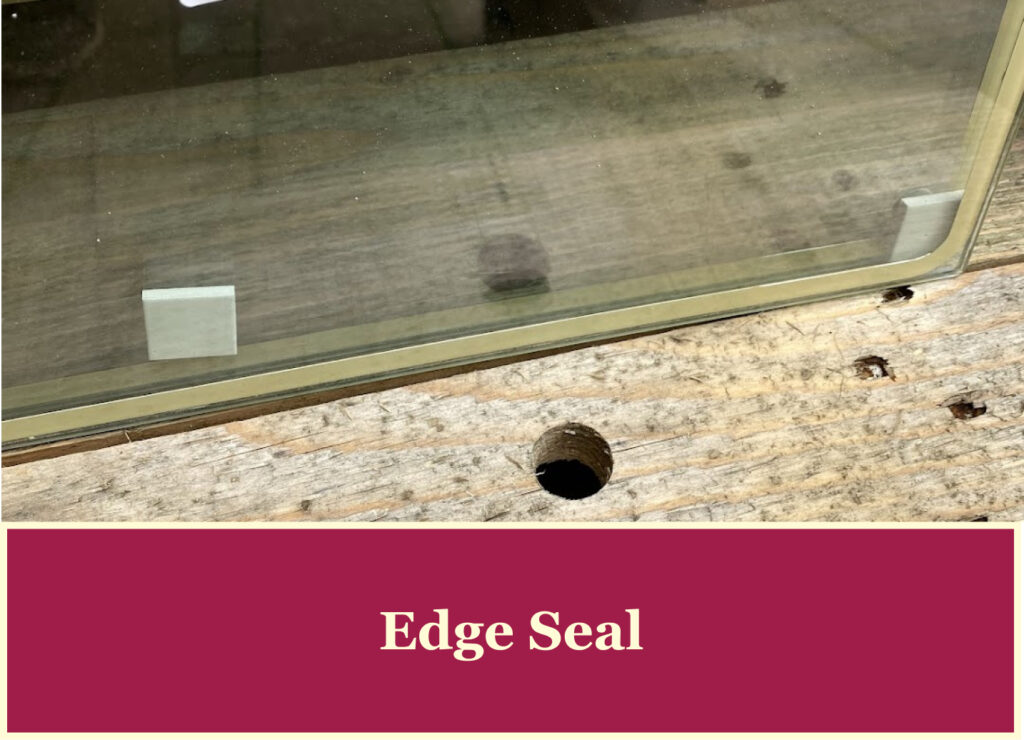

Edge Seal

The edges of the panes are sealed using a metallic or ceramic edge seal, often made of metal solder or other durable materials to ensure the vacuum remains intact over the long term.

Vacuum Gap

A micro-sized vacuum gap between the two panes eliminates the need for a gas filling. This vacuum is key to preventing heat conduction and convection.

Evacuation port – the design feature of the past

The evacuation port is a small hole in VIG unit that allows air to be evacuated between the glass panes, creating a vacuum.

This port was then sealed to maintain the vacuum over time.

Early VIG products, in particular LandVac and Pilkington, used to have a small evacuation port. However, over the years, LandVac has worked to make evacuation port less noticeable or eliminate them entirely.

Getters

A getter is a material used in VIG to maintain the vacuum inside the glazing unit over time. Its role is to absorb any gas molecules or contaminants that may remain or slowly leak into the vacuum space. Since even small amounts of gas can reduce the insulating efficiency of the vacuum, the getter ensures that the vacuum remains stable and effective for many years.

The getter may appear as a thin strip along the edges or corners of the glass unit, or a small circular or rectangular metal piece.

Advantages of vacuum glazing

Superior thermal insulation

One of the primary benefits of VIG is its exceptional thermal insulation properties.

A piece of VIG can provide a better heat insulation effect than a 1.5 m thick brick wall.

With a vacuum between the glass panes, there is virtually no conductive or convective heat loss, making it highly efficient at retaining heat during winter and keeping interiors cooler during summer.

This helps to reduce energy consumption, save on energy bills and create a more comfortable living space. It is especially beneficial for listed historic properties or older homes that tend to lose heat easily.

Soundproofing benefits

In addition to thermal insulation, VIG offers notable soundproofing advantages.

The vacuum layer works as a barrier to sound waves, significantly reducing noise pollution from outside and offering a quieter living space.

It is especially helpful if you live near roads with extensive traffic or in busy urban areas.

Low-E coating

The Low-E (low-emissivity) coating is a thin, invisible layer on the glass surface that improves energy efficiency.

This coating works by reflecting infrared heat while allowing visible light to pass through, which helps to retain warmth inside during winter and blocks solar heat in the summer.

Combined with the vacuum layer, the Low-E coating significantly enhances insulation, resulting in much lower U-values — typically between 0.4 to 0.7 W/m²K.

This makes VIG with Low-E coatings one of the most thermally efficient window solutions available.

Additionally, the Low-E coating reduces UV rays, helping to keep interior furnishings and surfaces from fading.

Despite its ability to reflect heat, the coating allows high levels of light transmission, ensuring rooms stay bright and comfortable without compromising on thermal performance.

Suitability for heritage buildings

For homeowners living in older or listed properties, maintaining the historic character of their windows is essential.

Vacuum glazing can be retrofitted into traditional window frames without altering their appearance.

The slim profile of VIG makes it possible to upgrade single-glazed windows with minimal impact on the visual integrity of the building, a crucial factor for heritage preservation.

Comparison with slimline double glazing

Slimline double glazing is another popular option for older homes, offering better insulation than single glazing while maintaining a slim profile.

Slimline double-glazing uses two panes of glass that are separated by a narrow gap, typically around 4-6mm, which is smaller than standard double-glazing cavities.

The cavity between the glass panes is typically filled with argon or krypton to ensure thermal insulation.

However, VIG outperforms slimline double glazing in terms of thermal efficiency and soundproofing thanks to the vacuum layer.

The vacuum chamber between glass panes in VIG provides much better insulation compared to the gas-filled cavity in slimline double glazing, making it a better long-term solution for homeowners focused on energy savings.

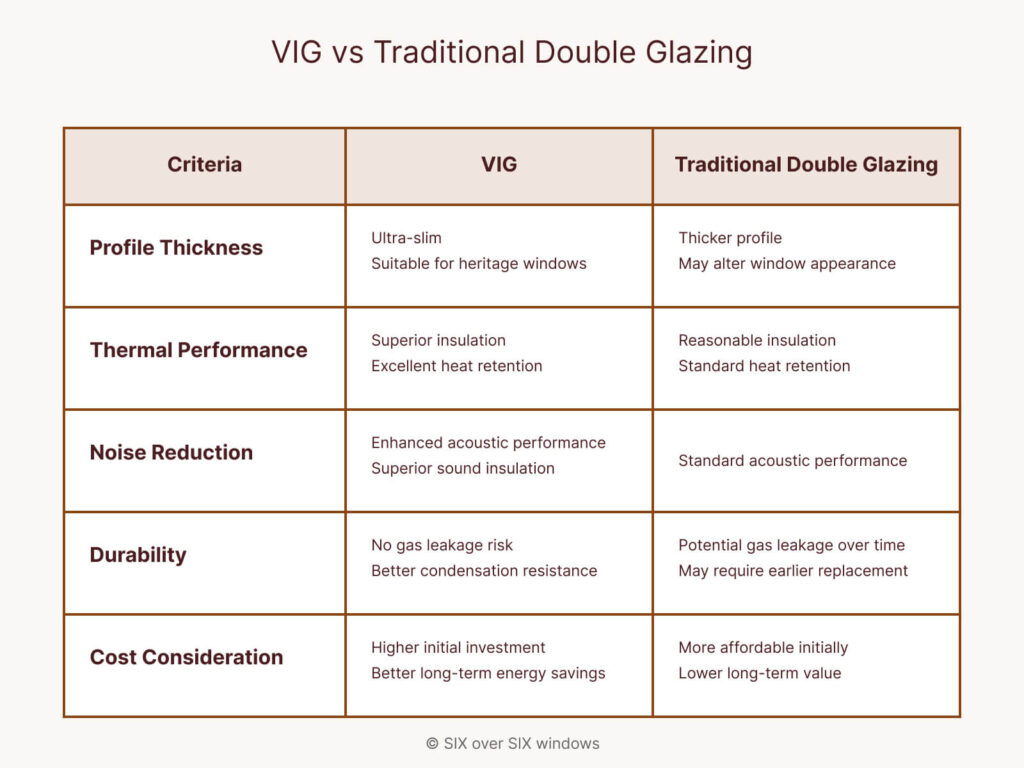

Comparison with traditional double glazing

While traditional double glazing is a common choice for modern homes, it is often not the best solution for heritage properties.

Standard double-glazing units are much thicker and can significantly alter the appearance of period windows, leading to potential complications with planning regulations in listed buildings.

Moreover, standard double glazing does not offer the same level of thermal performance as VIG, particularly in older homes that struggle with heat retention.

Traditional double glazing offers reasonable noise reduction of up to 34dB but does not match VIG’s acoustic performance, which can be a key factor for homeowners seeking a quieter living space.

Durability is also a significant consideration. The gas in traditional double glazing can leak over time, reducing its effectiveness, which may require earlier replacement.

Additionally, VIG’s resistance to condensation between the glass panes adds to its longevity and performance reliability.

Traditional double glazing is more affordable but may not meet the long-term energy savings or aesthetic requirements of older buildings.

Popular VIG glazing brands

LandVac

LandVac uses toughened glass to assure exceptional strength and longevity, which makes it suitable for various restoration projects, including the modernization of large windows. Initially, LandVac had an evacuation port, but newer models no longer require it, further improving the window’s aesthetics and performance. Its robust construction and high insulation efficiency make it a top choice for both modern and period properties.

Fineo

Fineo glass is known for its ultra-slim profile and high energy efficiency, making it ideal for retrofitting heritage windows. A standout feature is that Fineo glazing does not require an evacuation port, which enhances its sleek appearance and structural integrity. It also offers excellent thermal insulation performance and sound reduction, while replicating the look of traditional single glazing.

For detailed pricing information and lead times, see our Fineo glass price and lead times guide.

HaanGlas

HaanGlas stands out for its balance between high thermal performance and aesthetic clarity. With fewer visible pillars compared to other VIG brands, it offers an unobstructed view, making it ideal for homeowners who prioritize appearance. HaanGlas also provides flexibility with custom shapes, such as arched or irregular windows. Its efficient insulation and customizable options make it a strong competitor in the VIG market.

Pilkington Spacia

As the first commercially available vacuum glazing product, Pilkington Spacia set the standard for VIG technology. Although it is no longer available for purchase, Pilkington Spacia remains highly regarded for its innovative design, which laid the groundwork for modern vacuum glazing systems.

Compare modern vacuum glazing options

| Feature | Fineo | LandVac | Pilkington Spacia | HaanGlas |

|---|---|---|---|---|

| Glazing unit thickness | 6-8mm | 8-10mm | 6-7mm | 8-10mm |

| Safety glass | Optional toughened glass | Toughened glass as standard | No | Toughened glass as standard |

| Thermal transmission (U-value) | 0.7 W/m²K | 0.4 – 0.7 W/m²K | 1.0 – 1.2 W/m²K | 0.4 – 0.7 W/m²K |

| Sound transmission | Excellent (Up to 35dB reduction) | Very Good (Up to 39dB reduction) | Good (30dB reduction) | Very Good (Up to 36dB reduction) |

| Light transmission | 80% | 75-85%, depending on the Low-E coating | up to 86% | up to 80% depending on the Low-E coating |

| Pillars per square meter | 2,776 dots | 267 dots | 2774 dots | 576 dots |

| Evacuation port | No | No | Yes | No |

| Suitable for heritage properties | Yes | Yes | Yes | Yes |

| Weight | Lightweight | Medium | Lightweight | Medium |

| Warranty | 15 years | 15 years | 10 years | 15 years |

| Life expectancy | High (50-year lifespan) | Moderate (30-year lifespan) | Moderate (30-year lifespan) | High (50-year lifespan) |

| Price range | High | High | High | Medium |

| Energy efficiency | Excellent | Excellent | Good | Excellent |

| Availability in the UK | Widely available | Available | Not available | Available |

Environmental impact and sustainability

Vacuum glazing is a great option for homeowners who want to do their part for the environment and reduce their carbon footprint.

VIG leads to lower energy consumption and fewer greenhouse gas emissions thanks to reducing the need for heating and cooling.

VIG products are designed with durability and longevity in mind, often lasting decades before needing replacement.

Additionally, many vacuum glazing units are manufactured using recyclable materials, and companies are increasingly focusing on making their production processes more environmentally friendly.

FAQ

Can vacuum glazing be installed in listed buildings?

Yes, vacuum glazing can be installed in historic windows. Its slim profile and unobtrusive design make it ideal for upgrading original sash windows without compromising the historical integrity of the property.

Is vacuum glazing more expensive than traditional double glazing?

While vacuum glazing tends to be more expensive upfront, its superior thermal performance can lead to significant energy savings over time, making it a cost-effective choice in the long run.

Does vacuum glazing improve sound insulation?

Yes, vacuum glazing offers excellent soundproofing due to the vacuum layer between the glass panes, reducing noise pollution from the outside.

How does vacuum glazing compare to slimline double glazing?

Vacuum glazing generally provides better thermal insulation and soundproofing compared to slimline double glazing, making it a more efficient choice for homes looking to improve energy performance without altering the appearance of their windows.

Adam Brick

Adam Brick