LandVac is a cutting-edge tempered vacuum glazing insulated with vacuum (VIG), designed to offer exceptional thermal insulation, making it a highly efficient alternative to traditional slim-profile double glazing.

As a UK homeowner, you may be familiar with standard double glazing, which consists of two glass panes of glass, and the gap between the panes is filled with air or gas to reduce heat transfer, and offers energy savings.

However, LandVac takes this concept to the next level by introducing a vacuum layer between the tempered glass panes, which virtually eliminates conductive and convective heat transfer.

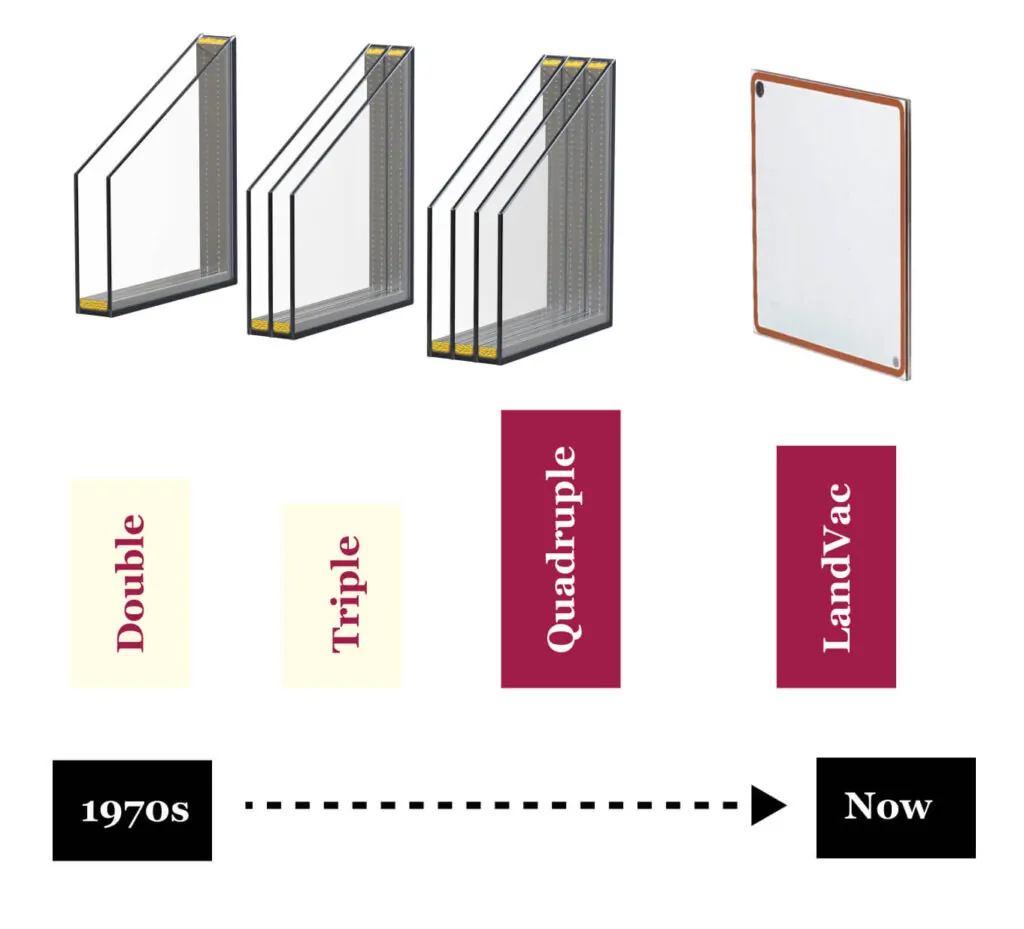

If you place LandVac on an insulated glazing units evolution graph, it would be positioned on the far right, representing the most recent and advanced technology in the insulated glazing industry.

Superior thermal performance in a slim profile

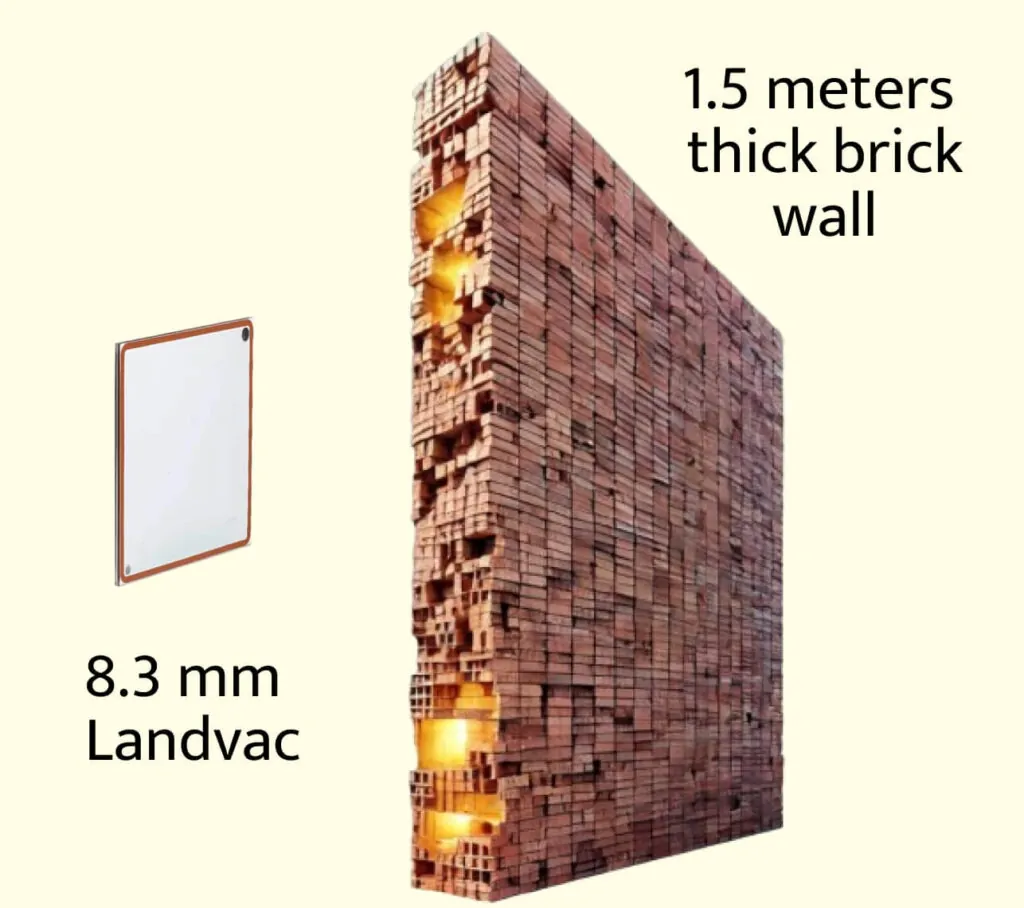

LandVac is impressively thin at just 8.3 mm. That’s thinner than an iPhone.

But it has better thermal insulation than a 1.5m thick brick wall.

While standard double glazing might have a U-value around 2-2.6 W/m²K, LandVac offers U-values as low as 0.4 W/m²K, making it ideal for reducing energy consumption in homes.

While Fineo glass may have caught your attention first, it’s worth considering other VIG brands like LandVac due to its distinctive features like toughened glass being used in the composition of the unit as well as better thermal performance.

VIG glazing units are thin enough to be installed into existing wooden windows in listed and period properties where replacement of the entire window is not possible.

LandVac vacuum glazing specification

| Warranty | 15 years |

| Estimated Lifespan | 25+ years |

| Years in market | 5 |

| Total glazing thickness | 8.3mm |

| Unit Make Up | 4TL+0.3V+4T 5TL+0.3V+5T 6TL+0.3V+6T Note: T – Toughened Glass; L – Low-E Coating; V – Vacuum Space |

| Vacuum cavity thickness | 0.3mm |

| Double reflection | None |

| Safety glass possible? | Safety glass as standard |

| U-value | 0.4 |

| Visible light transmission | 53-78% |

| Sound Reduction Index (Rw) | 36-39dB |

| Plugs | No (New design does not have plugs) |

| Getters | 3mm thick strip along a long edge |

| Other Markings | Unmarked: no logo, no safety glass markings. Safety glass marking can be added if required |

| Microspacers | At 70mm centres |

| Microspacers/m2 | 267 |

| Lead time | 10 weeks |

| Manufacture Location | China |

| Lead-free | Yes |

| Fully Recyclable | Yes |

Design features of LandVac and VIG glazing units

LandVac has a number of common design features with other VIG glazing, which are the following:

Support pillars

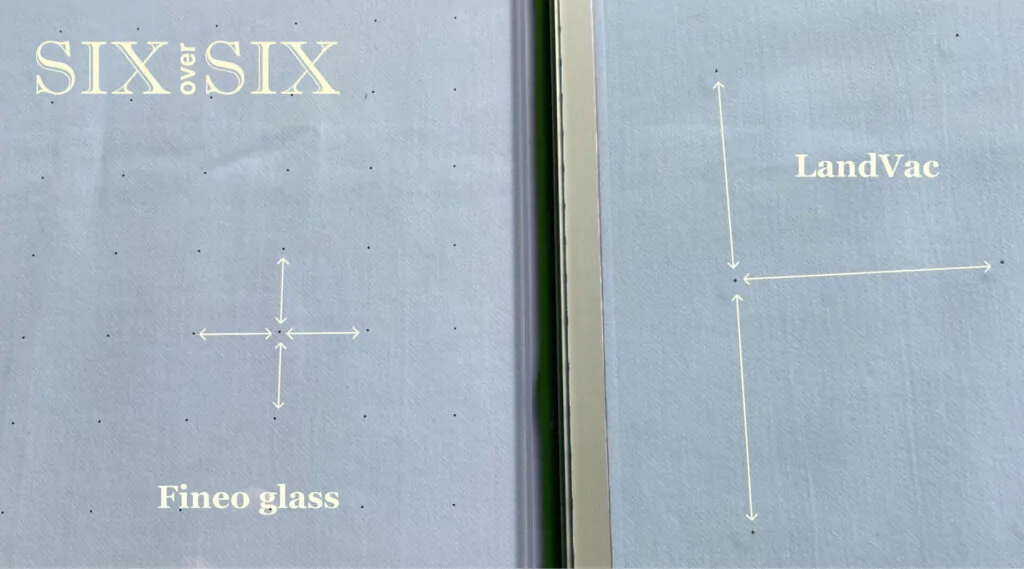

Pillars: LandVac uses small, invisible pillars spacers between the two glass panes that prevent the glass from collapsing under atmospheric pressure. These pillars are so tiny that they do not interfere with visibility or aesthetics, ensuring that your windows look sleek while providing the benefits of high thermal insulation performance.

Compared to FINEO glass, LandVac has fewer pillars per square centimetre which makes it more visibly appealing.

High vacuum chamber

High vacuum chamber – 0.3 mm: This vacuum layer sits between the two glass panes. Since there’s almost no air or gas inside the chamber, it eliminates heat transfer through convection or conduction.

Evacuation Port/Getters:

Evacuation Port/Getters: Older versions of LandVac used to have an evacuation port/getter hole, which allowed for pressure checks.

An evacuation port is a small opening in vacuum-insulated glazing used during production to remove air between the glass panes and create a vacuum.

A getter is a material used in vacuum-insulated glass (like LandVac) to maintain the vacuum inside the glazing unit over time. Its role is to absorb any gas molecules or contaminants that may remain or slowly leak into the vacuum space. Since even small amounts of gas can reduce the insulating efficiency of the vacuum, the getter ensures that the vacuum remains stable and effective for many years.

No evacuation port since 2023: The latest design no longer includes the evacuation port, and the getter has been converted to a slim strip along the edge of the glazing unit, resulting in a cleaner and more aesthetically pleasing finish.

Edge sealing

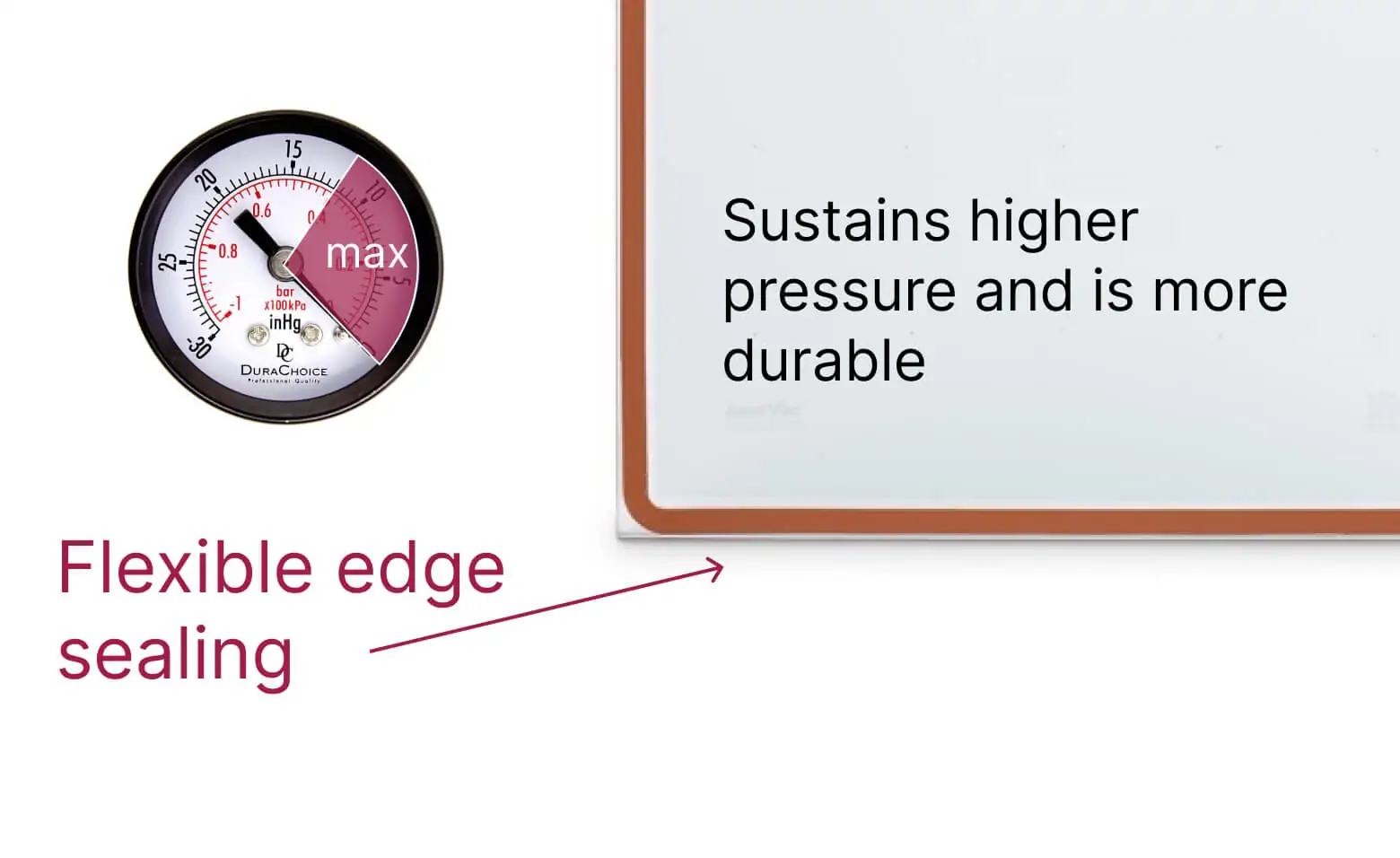

Can sustain higher levels of vacuum pressure: With the assistance of built-in high-efficiency getter material, it can sustain a high level of vacuum for a long time.

Flexible edge sealing: LandVac uses flexible edge sealing to maintain the vacuum between the inner and outer glass surfaces, ensuring long-term performance. This flexible edge material is highly resistant to thermal expansion and temperature differences, which commonly cause sealing failure in traditional glazing with brittle edge sealing materials. LandVac’s seals have higher thermal resistance, preventing damage even in extreme conditions.

Low-E Lamination:

Low-E Lamination: Like most modern insulated glazing units, LandVac includes low-emissivity (low-E) coatings on its glass panes. These coatings reduce the amount of infrared and ultraviolet light that passes through, helping to keep your home warm in winter and cool in summer by reflecting heat back into the room.

Toughened as standard: Key difference vs other VIG glazing options

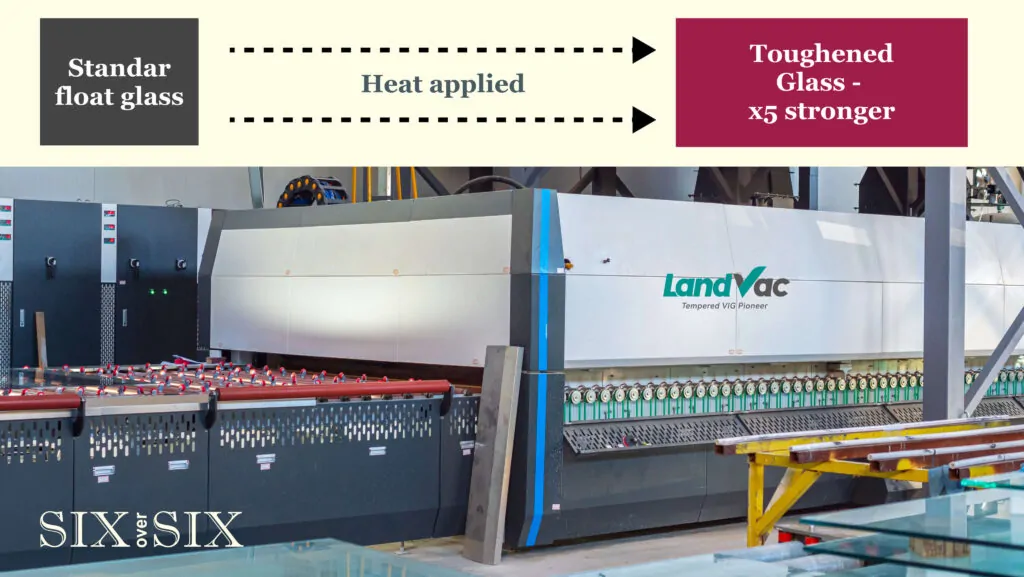

One key feature that sets LandVac apart from many other VIG options is that it is toughened as standard.

Toughened glass is a safety glass that has been heat-treated to make it significantly stronger than regular glass (5 times stronger).

This process makes the glass much more resistant to impact and, in the rare event that it does break, it shatters into blunt small pieces rather than dangerous sharp shards.

Surface stress and texture meet tempered glass standards, ensuring wind resistance of up to ±7200 Pa. This makes it ideal for high-wind environments such as coastal regions or high-rise buildings.

For homeowners, this feature ensures a higher level of safety, especially in homes with children or in areas prone to accidents.

Toughened glass also adds to the durability and longevity of the window, making LandVac an excellent long-term investment.

Energy efficiency and thermal performance

One of the primary reasons UK homeowners consider vacuum-insulated glazing like LandVac for its superior energy efficiency and durability.

LandVac’s thermal performance is unparalleled, with a U-value of 0.4 W/m²K.

This makes it one of the most thermally efficient glazing solutions available today, offering a significant reduction in heat loss compared to standard double glazing.

The vacuum layer within the glazing acts as a highly effective insulator, blocking heat transfer through the window.

Ultra-low dew point

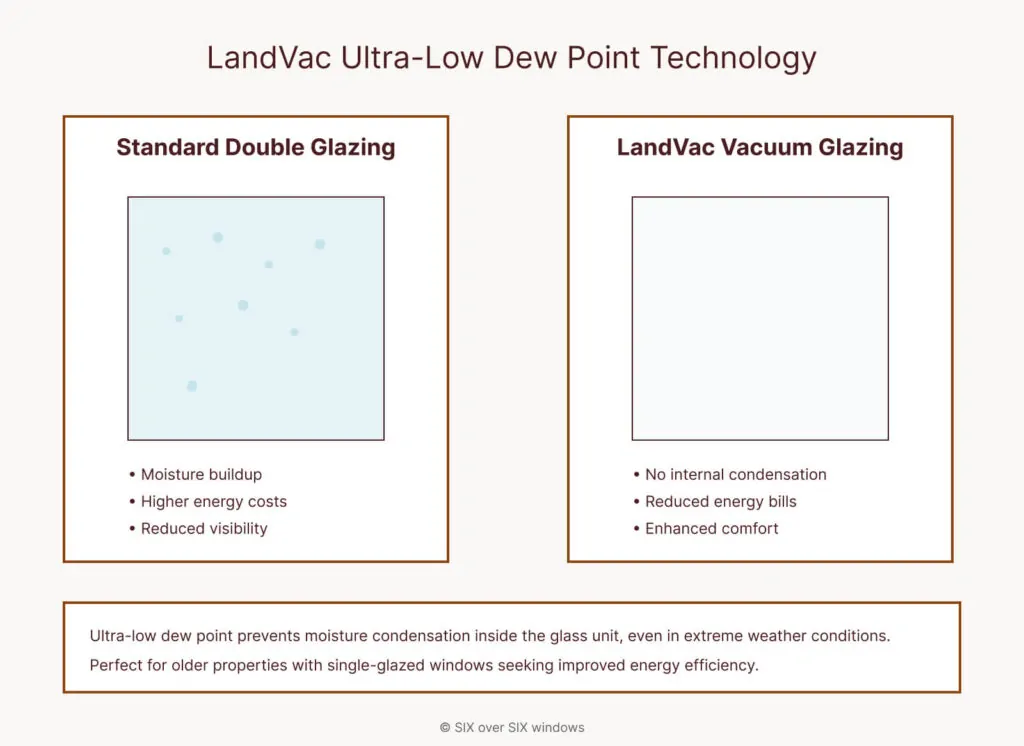

The ultra-low dew point in LandVac vacuum glazing refers to its ability to prevent condensation from forming inside the glass unit, even in extreme weather conditions. The dew point is the temperature at which moisture in the air condenses into liquid water.

This means homeowners save a lot on energy bills in the long run, especially in older properties with single-glazed windows.

By upgrading to LandVac, you could reduce your energy consumption, making your home more eco-friendly while also enhancing comfort.

There are also many durability benefits of LandVac compared to slimline double glazing, but we will cover this in our future articles.

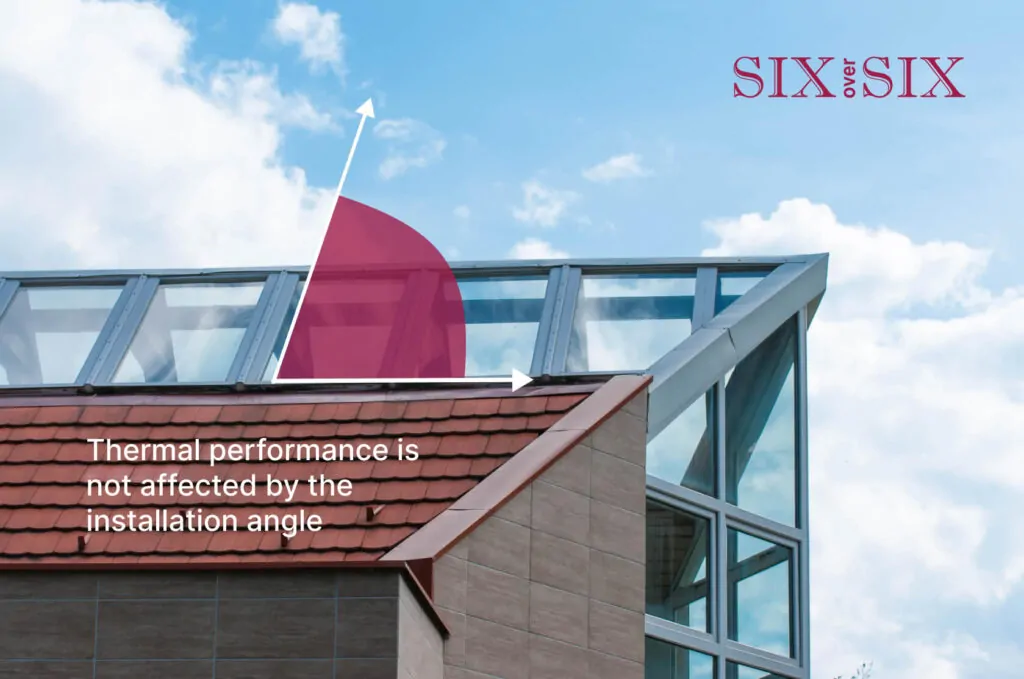

Thermal performance is not affected by the installation angle

LandVac’s thermal performance remains consistent regardless of the installation angle due to its vacuum layer between the glass panes.

Since there’s no medium inside the vacuum to transfer heat, the angle at which the glass is installed doesn’t impact its ability to insulate.

Whether the glass is installed vertically, horizontally, or at an angle, the vacuum’s insulating properties stay the same.

Noise reduction – windows soundproofing

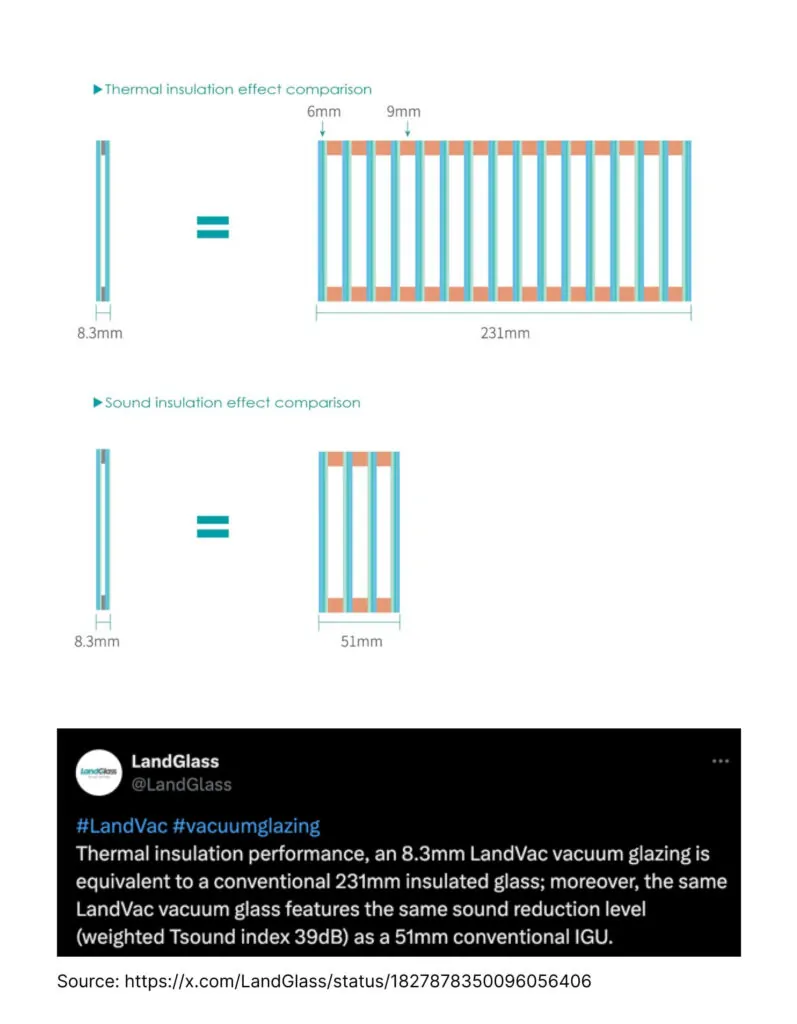

LandVac not only offers thermal insulation but also provides noticeable sound insulation against medium and low-frequency noises such as road traffic or construction noises.

The vacuum layer between the glass panes significantly reduces sound transmission, as there is no medium (like air or gas) to carry sound waves.

LandVac offers a noise reduction of approximately 36-39 dB this makes LandVac an excellent choice for homeowners seeking to minimize outdoor noise level, particularly in busy urban areas or homes near roads with heavy traffic.

LandVac vacuum glazing can be used for reglazing windows in listed buildings

LandVac’s slim profile, at just 8.3 mm thick, makes it an ideal choice for reglazing period properties, including listed buildings.

In the UK, many listed building homeowners face restrictions on replacing the original windows in their historic properties, making LandVac’s slim design ideal for installation into existing wooden sashes and preserving the original windows instead of replacing them.

We have installed LandVac glazing in numerous period properties, including listed buildings, where it seamlessly integrates with the original window design.

This ensures that homeowners can enjoy enhanced thermal performance without compromising the historic character of their home.

Our team completed a number of projects where we retrofitted vacuum double glazing into existing window frames

Installation process and compatibility with existing frames

One of the key advantages of LandVac is its compatibility with existing wooden window frames, making it a perfect solution for homeowners looking to upgrade from single glazing.

The 8.3 mm thickness allows it to fit into the narrow rebates commonly found in period windows, meaning you can keep your original frames while drastically improving the energy efficiency of your home.

Skilled professionals remove the old single-glazed panes and install LandVac units in their place, ensuring a perfect fit with your original frames.

This means you can retain the charm of your period windows and benefit from modern technology.

Frequently asked questions (FAQs)

How long does LandVac vacuum glazing last?

LandVac comes with a 15-year warranty and 25+ year life expectancy.

Can LandVac be installed in my existing wooden frames?

Yes, LandVac is specifically designed to fit into existing wooden frames, even those with narrow rebates commonly found in older properties. Contact us for a quote 🙂

How does LandVac compare to Fineo?

Both LandVac and Fineo are high-quality vacuum insulated glazing products, but LandVac offers toughened glass as standard, providing enhanced safety and durability. Additionally, the design of LandVac has evolved to remove the evaluation port, offering a cleaner aesthetic.

Is LandVac suitable for listed buildings?

Yes, LandVac’s slim profile and ability to fit into existing frames make it an excellent option for listed buildings where maintaining the original appearance is important, however, you still need to apply for planning permission.

What is the U-value of LandVac?

LandVac offers an impressive U-value of 0.4 W/m²K, making it one of the most thermally efficient glazing options available.

Can Landvac vacuum glazing be produced in special shapes?

Yes, LandVac vacuum glazing can be customized to fit special shapes such as arches, circles, or triangles. For non-standard shapes, the width-to-height maximum ratio is 1:6 for 8.3mm thickness. LandVac can produce any shape with a right angle and a single point of radius, isosceles triangles or right-angled triangles (hypotenuse greater than 370mm).

How does the thermal performance of triple glazing compare to that of LandVac?

Triple glazing uses three panes of glass with insulating gas between them, LandVac’s vacuum layer eliminates heat transfer through convection and conduction. Triple glazing typically has a U-value of around 0.8-1.2 W/m²K, whereas LandVac can achieve U-values as low as 0.4 W/m²K, making it more efficient at reducing heat loss. Additionally, LandVac is much thinner than triple glazing, making it a better fit for retrofitting older or listed buildings.

What are the minimum and maximum sizes that LandVac units can be produced in?

The minimum size for a LandVac unit is typically around 300 mm x 300 mm. The maximum size can go up to approximately 1500 mm x 3000 mm.

Adam Brick

Adam Brick