In a previous piece, we looked at the history and cultural significance of the sash window. Below will be an examination of historical sash window hardware and some of the changes that took place over time.

From the earliest iterations of sash windows there was accompanying hardware, whether that was pegs, to hold the window open in early examples prior to the weight and pulley system, or later in the form of heavily embellished and ornate Victorian sash lifts.

These changes, over the period from the early 1700s through to the modern-day, offer many interesting insights into the technical capabilities, as well as changing tastes of the age.

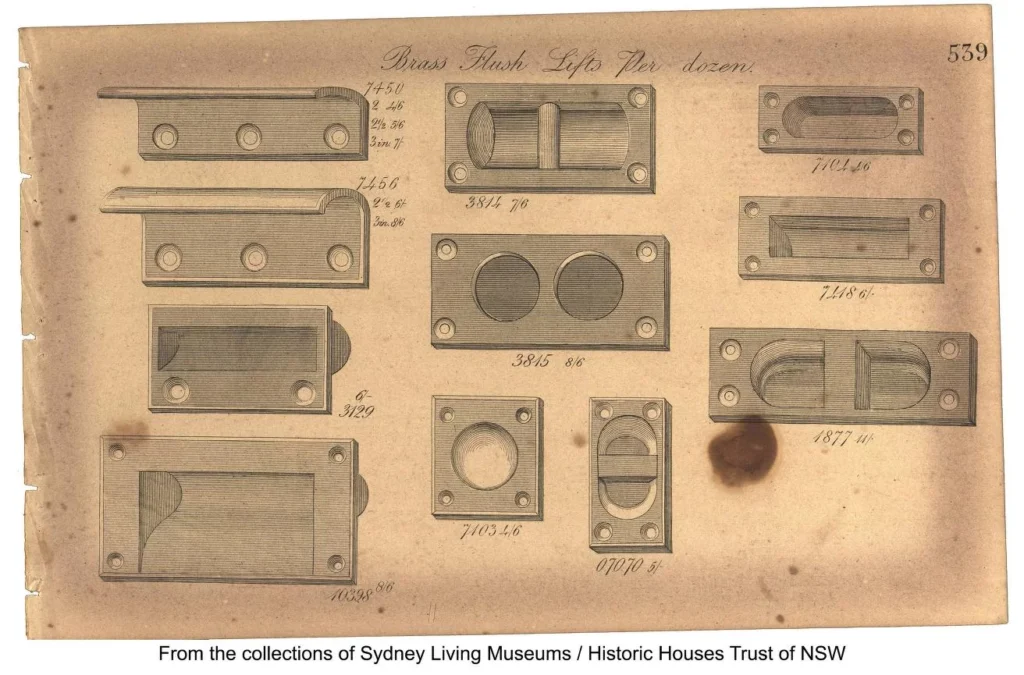

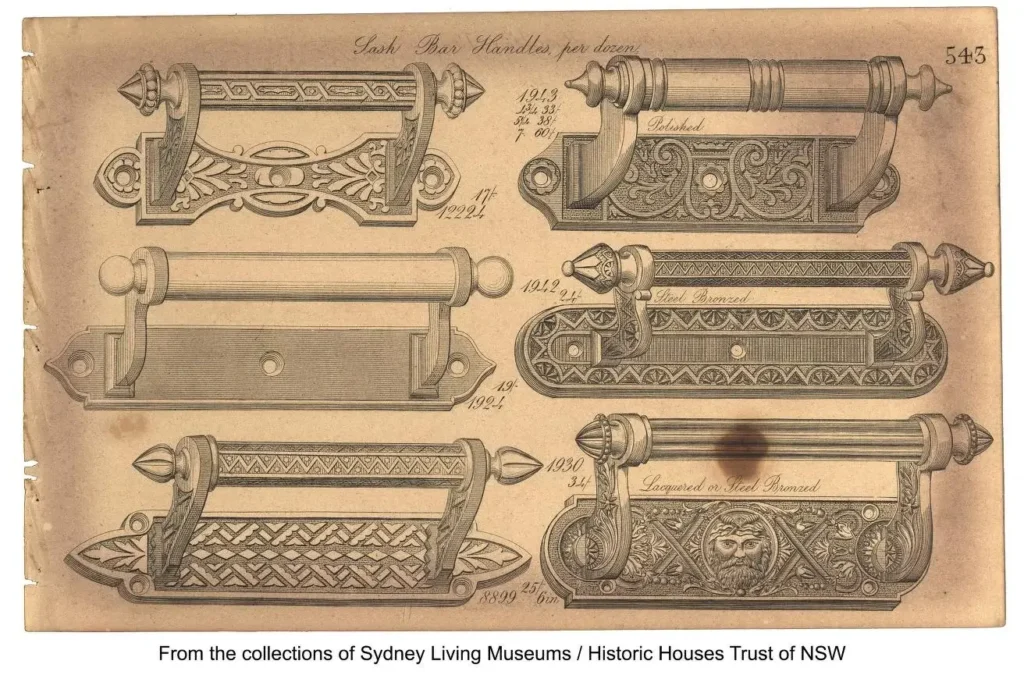

Sash lifts and pulls

Sash pulls allow for an easier opening of the window by providing a practical lift point. Attached to the inside face of the lower sash, the designs most commonly included hook, handle, recessed and loop varieties.

Design style varied greatly over time from the simple through to the heavily stylised. Below are Victorian-period examples illustrating some of these differences:

Ornate hinged sash lifts, with the top left design bearing classical-style embellishment work modelled on Greco-Roman columns (Page 566, James Cartland & Son general brass foundry)

Simple sash recess lifts (Page 567, James Cartland & Son general brass foundry)

More ornate sash lift handles (Page 571, James Cartland & Son general brass foundry)

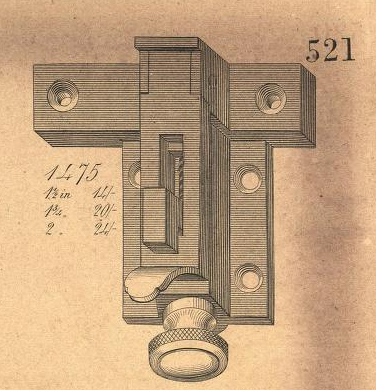

Sash fasteners and catches

“The earliest evidence of the use of a sash-bolt on a meeting rail that we have found is in the King’s Private Apartments on the ground floor in the William & Mary Block, Hampton Court, datable to c. I69I”

-Page 223, H. Louw, ‘A Constructional History of the Sash-Window, c. 1670-c. 1725 (Part 2)’

Sash fasteners were the mechanism that allowed for the sash windows to be fixed in a closed position. Some of the key designs were:

-The quadrant fastener: most common through the 1700s and the Georgian iterations of the sash. Consists of a plate with a lever attached to the top sash which, when moved through 90 degrees, locks into a receiving mechanism on the lower sash

-The claw fastener: many similarities to the quadrant fastener except that the hook body is fixed to the bottom sash and the keep plate to the top

-The fitch fastener: this design was very popular through the 1800s and remains in heavy use to this day. Again, the body is fixed to the lower sash with the fixture rotating into a clasp catch on the top sash

A U.S advertisement for a fitch lock 1896 (Page 13, The Journal of Preservation Technology…)

Other notable variations of the sash fastener include the “Brighton Pattern”, a spring-loaded device that bolted the two windows together. This security-focussed piece of sash hardware, alongside the Fitch, remains popular to this day. Earlier variants featuring springs in the locking mechanism (pictured below) begin to appear towards the end of the 19th century.

An early example of spring-loaded fastener from 1886 (Page 549, James Cartland & Son general brass foundry…)

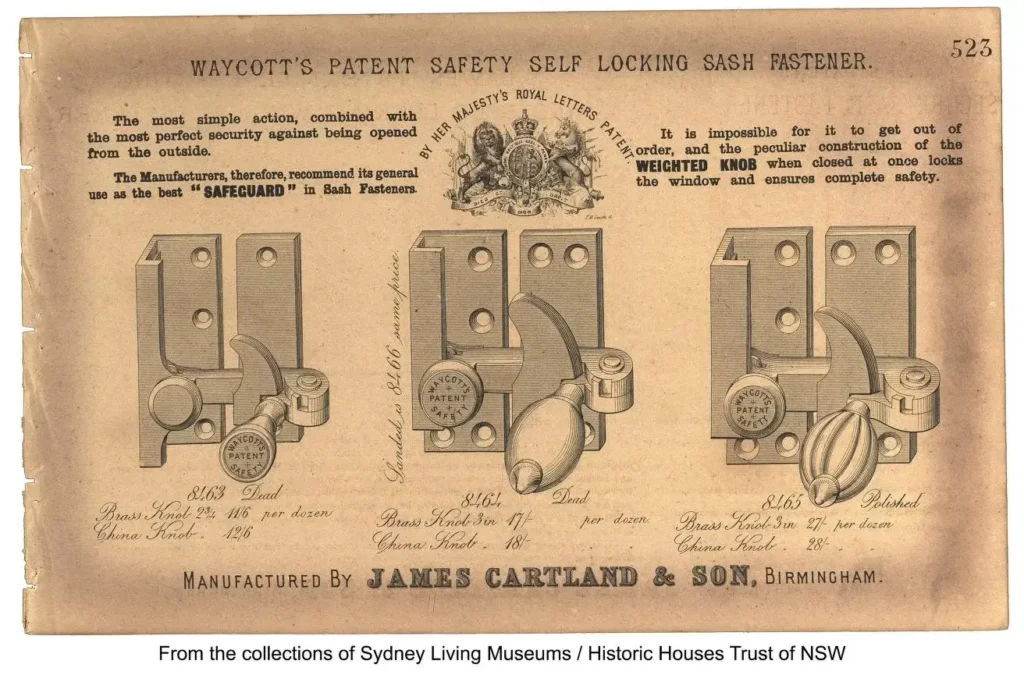

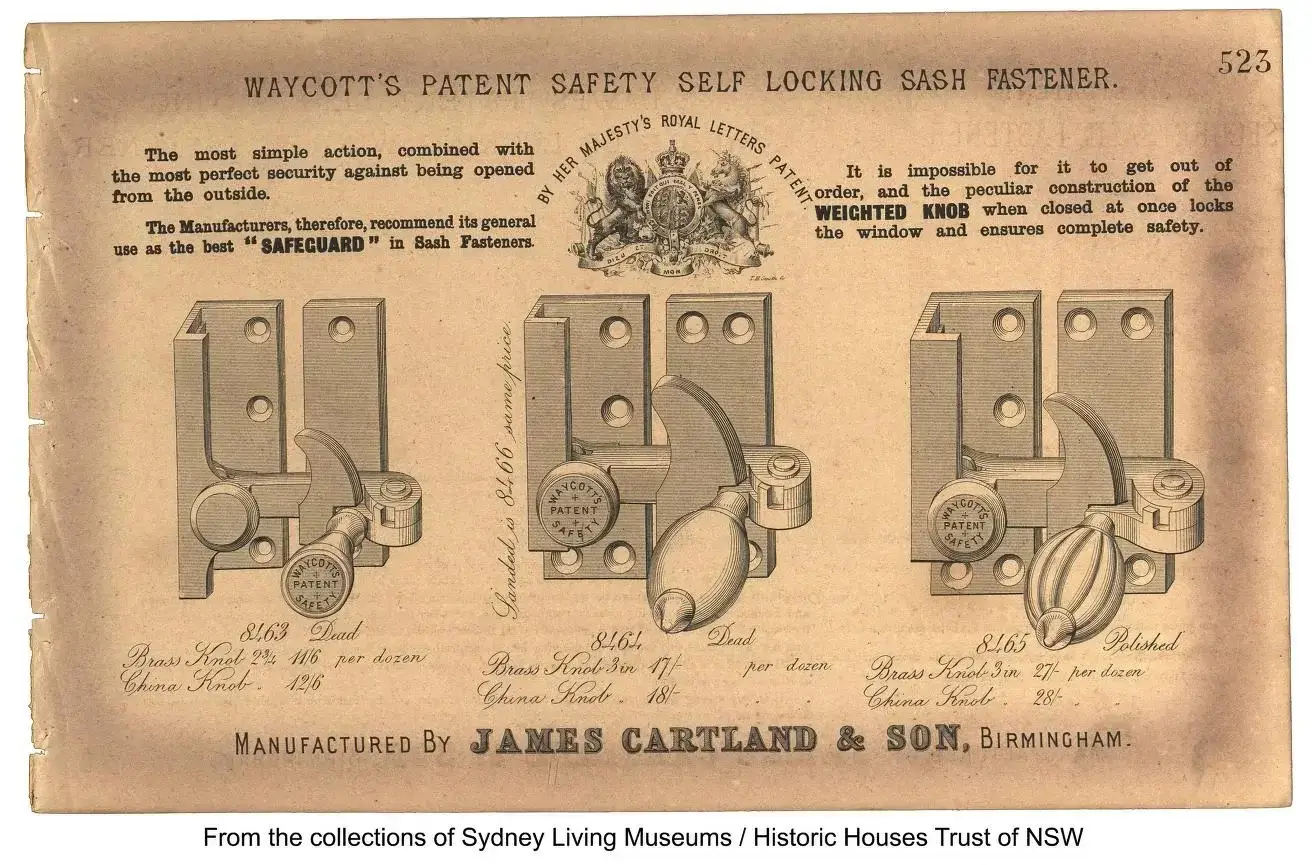

Often, sashes would have been paired with external shutters so security was not necessarily the main focus of the fastener/catch. However, over time (and certainly into the Victorian period of 1837-1901) security principles were incorporated into the action of the fastener, as seen below in an example of one of the innovative patents for a self-locking sash fastener from 1886:

(Page 551, James Cartland & Son general brass foundry)

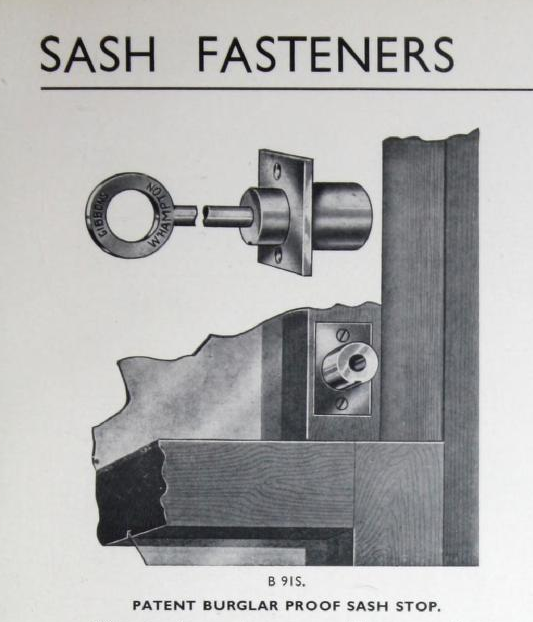

Through to a 1950’s example below of a ‘burglar proof’ sash stop, with the same security principles in mind, it fixes on the top sash and allows the windows to open the distance the fixture is placed above the meeting rail (in this case a recommended 7.5 inches). This would allow for ventilation but not enough space for a person to gain access through:

Burglarproof sash stop (Page 107, Architectural fittings by James Gibbons, 1952)

Sash window pulleys

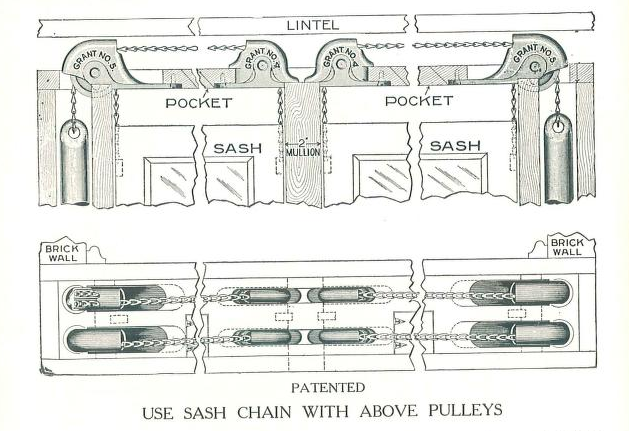

(Page 24, Grant Pulley 1900…) (Page 31, Grant Pulley 1900…)

Sash window pulleys are the mechanism through which the sash rope/chain is fed as the window is open and closed. A reliable pulley system is a key to the proper functioning of the window.

Through the Victorian period, a rope pulley system was most common, split into two grades- ‘ordinary’ and ‘best’. ‘Ordinary’ usually featured cast iron axle pulleys while ‘best’ grade incorporated a ball bearing in the design to reduce friction and, commonly a brass or bronze faceplate. However, into the 20th century much development focussed on a chain system with increased durability and for cost-efficient use at a large scale.

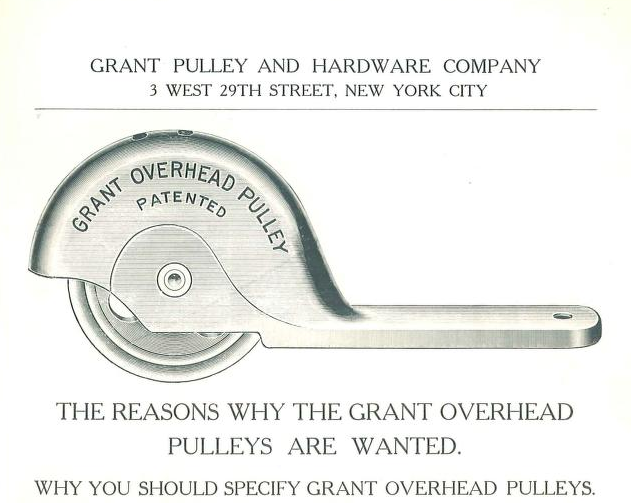

Early 20th Century U.S sash pulley system (Page 4, Grant overhead sash pulleys 1911…)

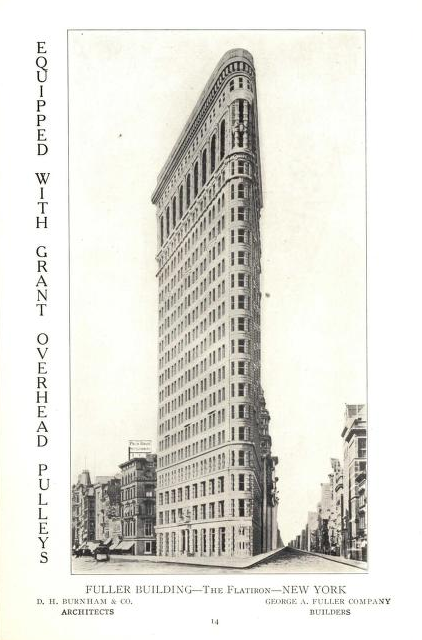

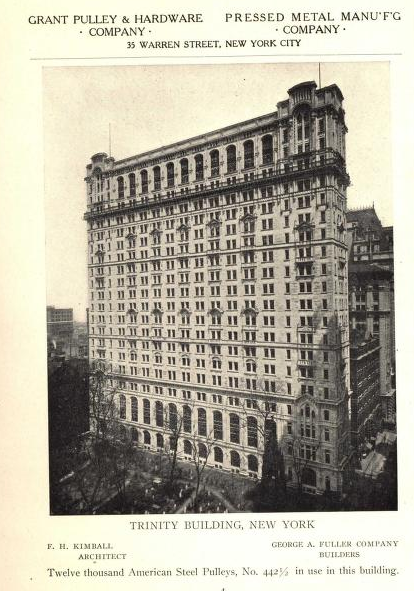

This is especially true in the United States, which drove a lot of the new demand for sash hardware through the late 19th and early 20th centuries. This is due to the fact that it was creating a huge amount of new buildings in these years, much of it emulating earlier European styles and therefore featuring sash windows.

This bolstered the, predominantly, private residential sash market in Europe helping to ensure that a new generation of sash windows would need maintenance and, therefore, parts and labour expertise well into the future. The Trinity building in New York below, for example, was fitted with 12,000 Grant steel sash pullies.

Examples of U.S buildings from this period employing sash windows & hardware, Fuller & Trinity building, New York (Left, Page 16, Grant Pulley 1900…) (Right, Page 6, Grant Pulley 1900…)

Miscellaneous sash fittings

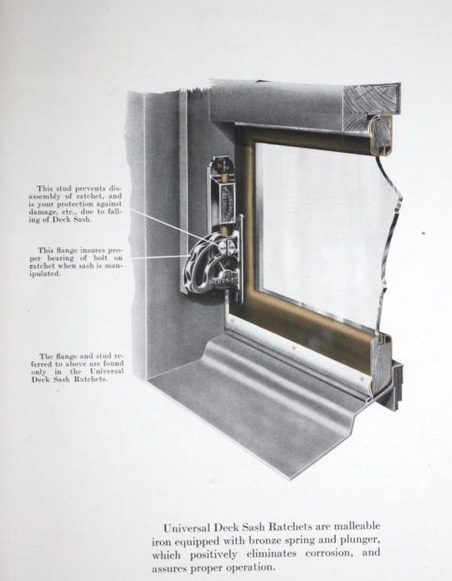

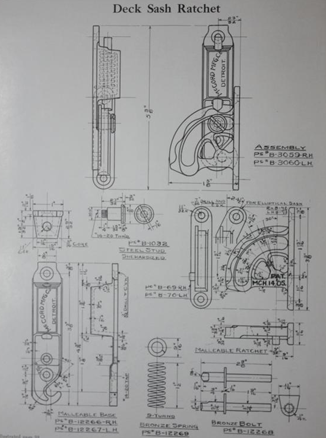

Many innovative design tweaks emerged in the 20th century, particularly alongside the US building boom and the need for larger industrial/public buildings employing sash-style windows.

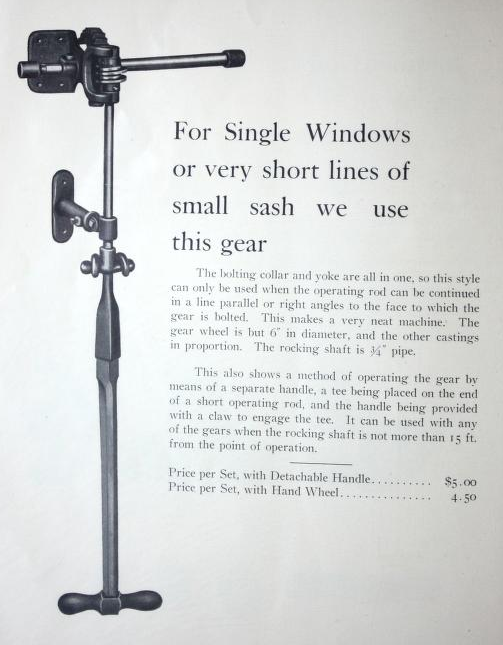

Examples below include new gearing mechanisms and ratchets for the safe opening and closing of windows (often at distance with the use of a pole if in a larger building).

(Pages 36 & 37, McCord Manufacturing, Universal window devices, 1900)

Operating pole for opening windows (Page 20, Catalogue of sash operating apparatus, 1915)

Adam Brick

Adam Brick